Kiʻekiʻe kiʻekiʻe hoolei kila pana me kiʻekiʻe kapa komo

Hoʻolauna

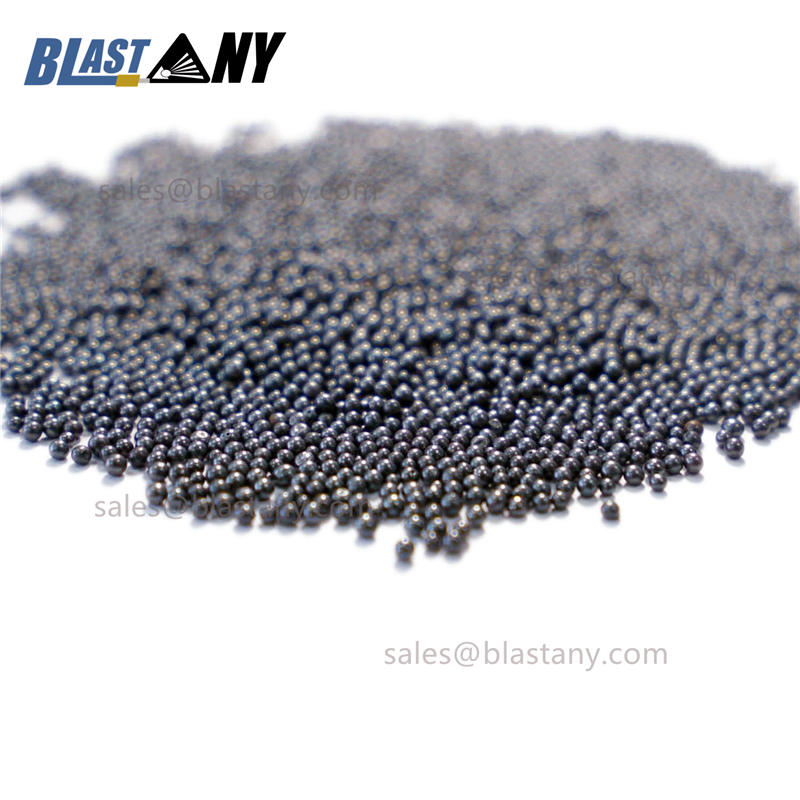

Hana ʻia ʻo Junda Steel Shot e ka hoʻoheheʻe ʻana i ka ʻōpala i koho ʻia i loko o ka umu induction uila.Hoʻopili ʻia ke ʻano kemika o ka metala hoʻoheheʻe ʻia a mālama pono ʻia e ka spectrometer no ka loaʻa ʻana o ka SAE Standard specification.Hoʻohui ʻia ka metala i hoʻoheheʻe ʻia a hoʻololi ʻia i ʻāpana poepoe a hoʻopau ʻia i loko o kahi kaʻina hana wela e loaʻa ai kahi huahana o ka paʻakikī like ʻole a me ka microstructure, nānā ʻia e ka nui e like me ka SAE Standard specification.

Junda 'oihana kila pana ua maheleia i eha, he aupuni maʻamau hoolei kila pana, i loaʻa chromium hoolei kila pana, pila no ka haʻahaʻa kalapona kila, kuhiliʻole kila, me ka lahui maʻamau hoolei kila pana ua loa e like me ka lahui maʻamau koi o ka mea maʻiʻo ma. hana, a me ka mea o ka chromium hoolei kila pana, ua hoʻokumu 'ia ma luna o ka 'āina maʻamau o ke kila poepoe, hoʻohui ferromanganese ferrochrome hooheheeia kaʻina hana i nā mea hana, e like me Owen ola lōʻihi;Haʻahaʻa kalapona kila pana hana kaʻina hana a me ka lahui maʻamau kila pana, akā, i ka maka mea he haʻahaʻa kalapona kila, kalapona maʻiʻo ka haʻahaʻa;Hoʻopuka ʻia ke kila kila ma ke kaʻina hana atomizing, nā mea maka he kila kila, 304, 430 stainless steel a pēlā aku.

Hana ʻia kēia ʻano pana no ka hoʻohana ʻana i nā kaʻina hana pana a me nā kaʻina hana ma lalo o ke kaomi ʻana e ka ea kōmi.Hoʻohana nui ʻia ia ma nā metala non-ferrous e like me ka aluminika, zinc alloys, stainless steels, keleawe, keleawe, keleawe ...

Hoʻohana ʻia ia no ka hoʻomaʻemaʻe, deburring, compaction, shot peening a me nā kaʻina hana hoʻopau maʻamau, ma nā ʻāpana āpau, me ka hoʻohaumia ʻole ʻana i kona ʻili e nā lepo ferrous e hōʻino a hoʻololi i ke kala o nā metala i mālama ʻia.no ka hana kahiko o ke kinikini a me ka granite.

Hoʻohana ʻenehana

Pahū kila

Hoʻomaʻemaʻe ʻia ke one hoʻoheheʻe a puhi ʻia - ma ke one o ka hoʻoheheʻe ʻana i mea e loaʻa ai ka maʻemaʻe maikaʻi o ka ʻili a me ka roughness pono, no laila hiki ke pōmaikaʻi i ka hana a me ka uhi ʻana.

Kiʻi kila kila no ka hoʻomākaukau ʻana i ka ʻili o ka pā kila

E hoʻomaʻemaʻe i ka ʻili oxide, ka ʻōpala a me nā mea haumia ʻē aʻe ma ke kī ʻana i ka pahu kila, a laila hoʻohana i ka mea hoʻomaʻemaʻe a i ʻole ka ea i hoʻomaʻemaʻe ʻia e hoʻomaʻemaʻe i ka ʻili o nā huahana kila.

Hoʻohana ʻia nā kiʻi kila no nā mīkini ʻenekinia

Hiki i nā kiʻi kila i hoʻohana ʻia no ka hoʻomaʻemaʻe mīkini hiki ke hoʻopau maikaʻi i ka ʻōpala, welding slag, a me ka ʻili oxide, hoʻopau i ke koʻikoʻi kuʻi, a hoʻonui i ka ikaika paʻa ma waena o ka uhi ʻana i ka ʻōpala a me ka metala, pēlā e hoʻomaikaʻi nui ai i ka maikaʻi derust o nā ʻāpana mīkini ʻenehana.

Nui pana kila no ka hoʻomaʻemaʻe ʻana i ka pā kila kila

I mea e loaʻa ai ka hoʻomaʻemaʻe, luminous, exquisite burnish surface treatment of stainless steel plate, pono ia e koho i nā mea abrasive kūpono e wehe i ka unahi mai ka ʻili kila kuhili ʻole.

E like me nā māka like ʻole, pono ke koho ʻana i nā abrasives diameter ʻokoʻa a me ke ʻano o ka hana.Ke hoʻohālikelike ʻia i ke kaʻina hana kemika maʻamau, hiki iā ia ke hoʻohaʻahaʻa i ke kumukūʻai hoʻomaʻemaʻe a hoʻokō i ka hana ʻōmaʻomaʻo.

ʻO ka pāpaʻi pahū kila no ka Pipeline anti-corrosion

Pono nā paipu kila i ka mālama ʻana i ka ʻili i mea e hoʻoikaika ai i ka pale ʻana i ka corrosion.Ma ke kila kila, hoʻomaʻemaʻe i ka media polishes, hoʻomaʻemaʻe a hoʻoneʻe i ka oxide a me nā mea hoʻopili e hoʻokō i ka ʻeleʻele i noi ʻia a me ka hohonu o ka palaoa, ʻaʻole wale ka hoʻomaʻemaʻe ʻana i ka ʻili akā hoʻomāʻona hoʻi i ka adhesion ma waena o ka paipu kila a me ka uhi, loaʻa ka hopena anti-corrosion maikaʻi.

ʻO ka hoʻoikaika ʻana i ka pana kila

ʻO nā ʻāpana metala i hana ʻia i ke kūlana hoʻouka cyclic a ma lalo o ke ʻano o ke koʻikoʻi o ke kaʻa kaʻa pono e hoʻoikaika i ke kaʻina hana peening e hoʻomaikaʻi i ke ola luhi.

Hoʻolei kila kila Nā kāhuna palapala

Hoʻohana nui ʻia nā kiʻi kila i ka hoʻoikaika ʻana i ka hana ʻana i nā ʻāpana koʻikoʻi e like me ka puna helical, ka puna lau, ka pahu wili, nā ʻāpana, nā ʻāpana hoʻoili, ka lawe ʻana, ka pahu cam, ka axle bent, ka lāʻau hoʻohui a pēlā aku.I ka pae ʻana o ka mokulele, pono e kūʻē ka mea hoʻokele i ka hopena weliweli e pono ai ka mālama ʻana i ka pana peening mau.Pono nō hoʻi nā ʻēheu i ka lāʻau hoʻokuʻu kaumaha.

Nā ʻāpana ʻenehana

| Papahana | Nā Kūlana Lahui | ʻAno maikaʻi | |

| ʻO ka hui kemika% | C | 0.85-1.20 | 0.85-1.0 |

| Si | 0.40-1.20 | 0.70-1.0 | |

| Mn | 0.60-1.20 | 0.75-1.0 | |

| S | <0.05 | <0.030 | |

| P | <0.05 | <0.030 | |

| ʻoʻoleʻa | pana kila | HRC40-50 HRC55-62 | HRC44-48 HRC58-62 |

| ʻO ka mānoanoa | pana kila | ≥7.20 g/cm3 | 7.4g/cm3 |

| Microstructure | Tempered Martensite a i ʻole Troostite | ʻO ka hui ʻo Tempered Martensite Bainite Composite | |

| Ka nana aku | pōʻai Nā ʻāpana ʻāha<10% ʻāpana māwae<15% | pōʻai Nā ʻāpana ʻāha<5% ʻāpana māwae<10% | |

| ʻAno | S70, S110, S170, S230, S280, S330, S390, S460, S550, S660, S780 | ||

| Hoʻopili | ʻO kēlā me kēia ton i kahi Pallet kaʻawale a me kēlā me kēia ton i māhele ʻia i nā ʻeke 25KG. | ||

| Ka lōʻihi | 2500~2800 manawa | ||

| ʻO ka mānoanoa | 7.4g/cm3 | ||

| Anawaena | 0.2mm, 0.3mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.4mm, 1.7mm, 2.0mm, 2.5mm | ||

| Nā noi | 1. Hoʻomaʻemaʻe pahū: Hoʻohana ʻia no ka hoʻomaʻemaʻe ʻana i ka hoʻolei ʻana, make-casting, forging;ka wehe ʻana o ke one i ka hoʻolei ʻana, ka pā kila, ke kila ʻano H, ka hale kila. 2. Hoʻokuʻuʻia ka'ōpala: Ka weheʻana i ka'ōpala o ka hoʻoleiʻana, ka hoʻouluʻana, ka pā kila, ke kilaʻano H, ke kila kila. 3. Paʻi kiʻi: Paʻi kiʻi ʻana o nā mea hana, nā ʻāpana i mālama ʻia me ka wela. 4. Pahu pana: Pahu pana o ke kila profile, papa moku, papa kila, mea kila, hale kila. 5. Hoʻomaʻamaʻa mua: Hoʻomaʻamaʻa mua ʻana i ka ʻili, ka papa kila, ke kila profile, ka hale kila, ma mua o ka pena ʻana a i ʻole ka uhi ʻana. | ||

Ka Laha ana o ka pana kila

| SAE J444 Kiʻi kila maʻamau | Pale No. | In | Nui pale | |||||||||||

| S930 | S780 | S660 | S550 | S460 | S390 | S330 | S280 | S230 | S170 | S110 | S70 | |||

| PALAPALA | 6 | 0.132 | 3.35 | |||||||||||

| Pau Pau | 7 | 0.111 | 2.8 | |||||||||||

| 90% min | Pau Pau | 8 | 0.0937 | 2.36 | ||||||||||

| 97% min | 85% min | Pau Pau | Pau Pau | 10 | 0.0787 | 2 | ||||||||

| 97% min | 85% min | 5% ka nui | Pau Pau | 12 | 0.0661 | 1.7 | ||||||||

| 97% min | 85% min | 5% ka nui | Pau Pau | 14 | 0.0555 | 1.4 | ||||||||

| 97% min | 85% min | 5% ka nui | Pau Pau | 16 | 0.0469 | 1.18 | ||||||||

| 96% min | 85% min | 5% ka nui | Pau Pau | 18 | 0.0394 | 1 | ||||||||

| 96% min | 85% min | 10% ka nui | Pau Pau | 20 | 0.0331 | 0.85 | ||||||||

| 96% min | 85% min | 10% ka nui | 25 | 0.028 | 0.71 | |||||||||

| 96% min | 85% min | Pau Pau | 30 | 0.023 | 0.6 | |||||||||

| 97% min | 10% ka nui | 35 | 0.0197 | 0.5 | ||||||||||

| 85% min | Pau Pau | 40 | 0.0165 | 0.425 | ||||||||||

| 97% min | 10% ka nui | 45 | 0.0138 | 0.355 | ||||||||||

| 85% min | 50 | 0.0117 | 0.3 | |||||||||||

| 90% min | 85% min | 80 | 0.007 | 0.18 | ||||||||||

| 90% min | 120 | 0.0049 | 0.125 | |||||||||||

| 200 | 0.0029 | 0.075 | ||||||||||||

| 2.8 | 2.5 | 2 | 1.7 | 1.4 | 1.2 | 1 | 0.8 | 0.6 | 0.4 | 0.3 | 0.2 | GB | ||

Hana Hana

Mea maka

Hoʻokumu

Hoʻomaloʻo

Ka nānā ʻana

Koho

ʻO ka hoʻohenehene

Ka nānā ʻana

Pūʻolo

Māhele huahana