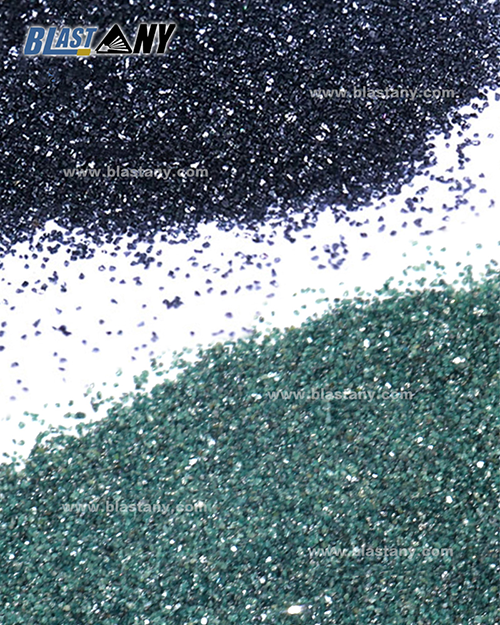

Maopopo iā ʻoe e pili ana i ka carbide silika ʻeleʻele a me ka carbide silika ʻōmaʻomaʻo?

Hua'ōlelo nui: #siliconcarbide #silicon #Introduction #sandblasting

● ʻEleʻele silikon carbide:Junda Silicon Carbide Grit ʻo ia ka mea paʻakikī pahū pahū i loaʻa. Hana ʻia kēia huahana kiʻekiʻe i kahi ʻano palaka, angular grain shape. E uhaʻi mau ana kēia pāpaʻi a hiki i ka ʻoki ʻoki ʻana i nā ʻaoʻao.

● Silicon carbide i loa kiʻekiʻe paakiki, me ka Mohs paakiki o 9.5, lua wale no ka honua paakiki daimana (10). He maikai loa thermal conductivity, he semiconductor, a hiki ke pale aku i ka oxidation ma kiʻekiʻe wela.

● Green silicon carbide:Green silicon carbide manufacturing method is like that of black silicon carbide carbide, but the clean of the raw materials used need a higher degere o ka maemae, It also forms green,semi transparent,hexagonal crystal shapes in a high temperature of about 2200℃ in a resistance furnace. ʻOi aku ka kiʻekiʻe o ka maʻiʻo Sic ma mua o ka silika ʻeleʻele a ua like kona mau waiwai me ka carbide silika ʻeleʻele, akā ʻoi aku ka liʻiliʻi o kāna hana ma mua o ka carbide silikon ʻeleʻele.

● Noi:

1. ʻO kaʻokiʻana a me ka wiliʻana i nā wafers solar, semiconductor wafers, a me nā'āpana quartz.

2.Polishing o ka aniani a me ka maemae palaoa hao.

3.Precision polishing a me ka sandblasting o nā seramika a me ke kila kūikawā.

4.ʻokiʻoki, manuahi manuahi a me ka polishing o nā mea hana abrasive paʻa a uhi ʻia.

5. ʻO ka wili ʻana i nā mea metala ʻole e like me ke aniani, ka pōhaku, ka agate a me ka jade jewelery kiʻekiʻe.

6.Manufacturing i nā mea refractory kiʻekiʻe, nā mea hana seramika, nā mea hoʻomehana a me nā mea ikehu wela, etc.

Ka manawa hoʻouna: ʻAukake-28-2024