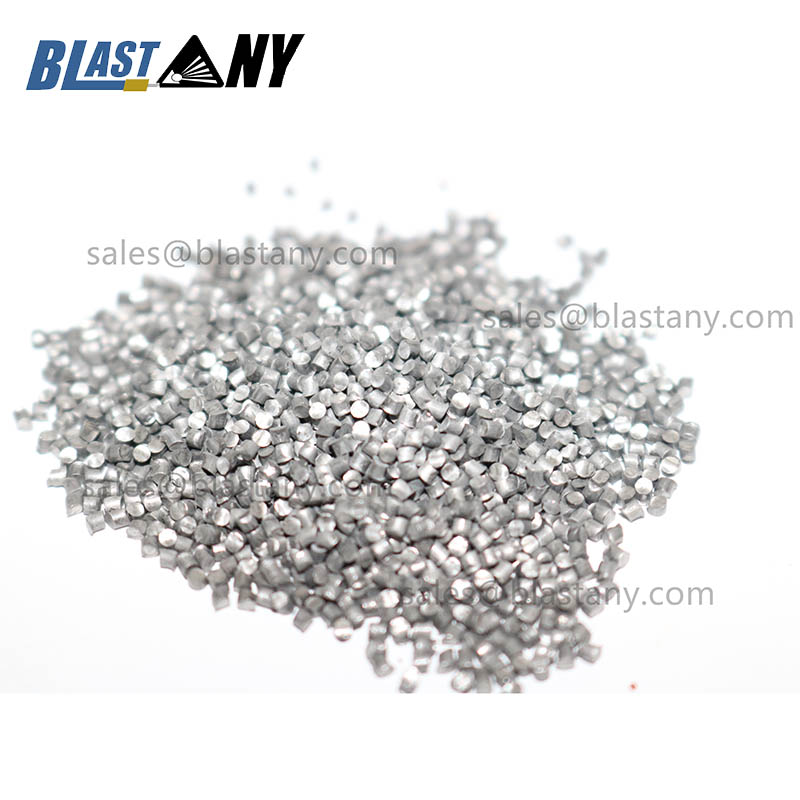

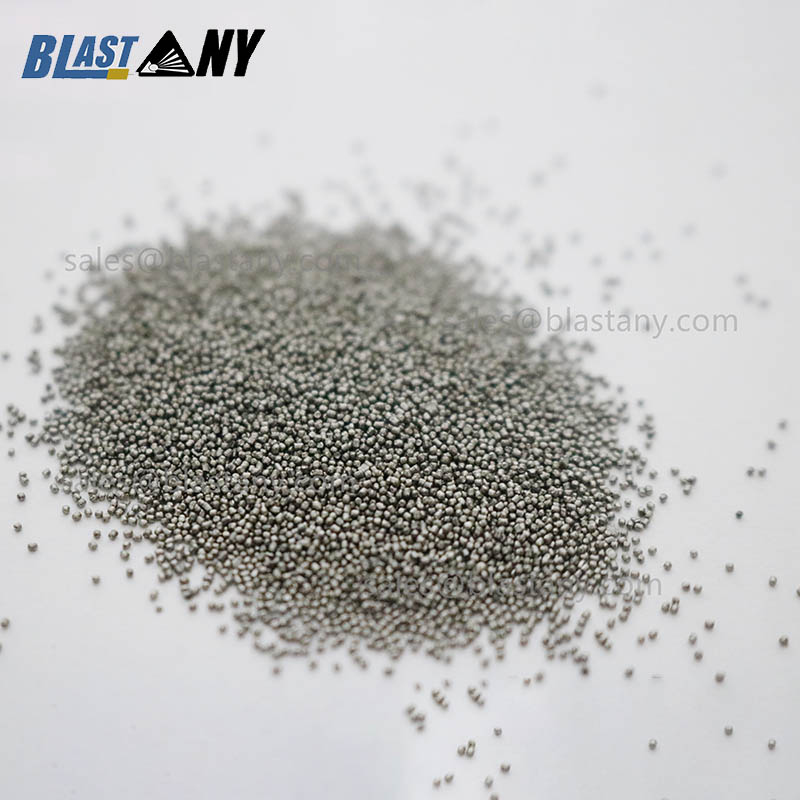

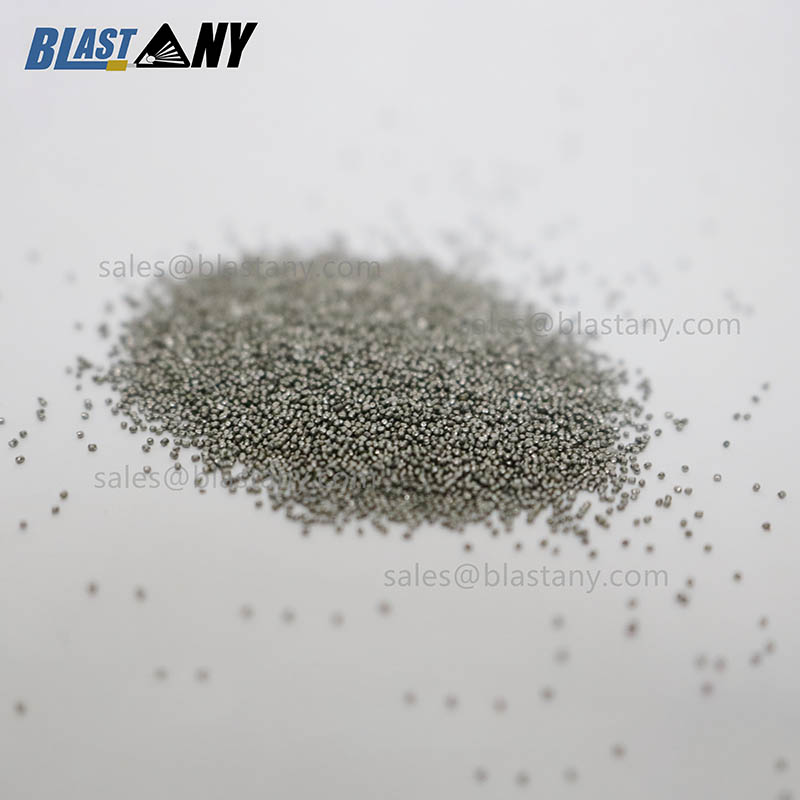

ʻOki Wire Shot kūʻē i ka ikaika kiʻekiʻe

ʻAno ʻoki ʻoki uwea kila

0.8mm 1.0mm 1.5mm 2.0mm 2.5mm

Ka laulā o ka hoʻohana ʻana i nā lāʻau ʻoki uea

1. ʻO ka hoʻoikaika ʻana i ka ʻoki ʻana i ka uwea kila: ka hoʻoikaika ʻana i ka puhi ʻana, ka hoʻoikaika ʻana i ka puhi ʻana i nā ʻāpana i mālama ʻia me ka wela, ka hoʻoikaika ʻana i ka pahu.

2. ʻO ka peening uea kila: ka peening kila, ke one kila, ka pahu moku, ka peening kila, ka peening kila.

3. ʻO ka hoʻomaʻemaʻe uea kila: hoʻomaʻemaʻe hoʻomaʻemaʻe, hoʻomaʻemaʻe hoʻomaʻemaʻe, hoʻomaʻemaʻe hoʻomaʻemaʻe, hoʻomaʻemaʻe hoʻomaʻemaʻe, hoʻomaʻemaʻe hoʻomaʻemaʻe hoʻomaʻemaʻe, hoʻomaʻemaʻe hoʻomaʻemaʻe hoʻomaʻemaʻe, hoʻomaʻemaʻe hoʻomaʻemaʻe hoʻomaʻemaʻe, hoʻomaʻemaʻe kila, hoʻomaʻemaʻe kila.

4. uea uea oki pana derusting: pana pahū derusting, pana peening derusting, hoolei derusting, forgings derusting paʻa kila derusting, forgings derusting, kila derusting, H-beam derusting hale derusting.

5. ʻO ke one ʻoki ʻoki uea kila: mālama one.

6. Ka uwea kila pana oki pretreatment: ka uhi mua, ka uhi pretreatment, ili pretreatment, moku pretreatment, pauku kila pretreatment, kila pretreatment, kila pretreatment, kila hooponopono pretreatment.

7. ʻO ka puhi ʻana i ka uea kila: ka pā kila kila, ka pahu kila, ka pahu kila.

ʻO nā lako kūpono no ka ʻoki ʻana i ke kī uea kila

Hoʻohana ʻia ka ʻoki ʻana i ka uea kila no ka laina hana hoʻomaʻamaʻa kila, ka laina hana hoʻomaʻamaʻa kila, ka laina hana hoʻomaʻamaʻa kila, ka mīkini hoʻoheheʻe ʻana, ka mīkini hoʻoheheʻe ʻana, nā mea hoʻoheheʻe kī, nā mea hoʻoheheʻe ʻana i ke one, nā mea hoʻoheheʻe one.

Nā ʻāpana ʻenehana

| Nā huahana | ʻOki Wire Shot | |

| C | 0.45~0.75% | |

| Mn | 0.40~1.20% | |

| Hoʻohui Kimia | Si | 0.10~0.30% |

| S | 0.04% | |

| P | 0.04% | |

| Microhardness | 1.0mm 51~53 HRC(525~561HV) | |

| ʻO ka ikaika ʻo Tensile | 1.0mm 1750~2150 Mpa | |

| ʻO ka mānoanoa | 7.8g/cm3 | |

Māhele huahana