AISI1010/1015/1085 kiʻekiʻe/haʻahaʻa kalapona kila poepoe 0.8 mm – 50.8 mm kalapona kila poepoe no ka paikikala huila kaulahao.

wehewehe huahana

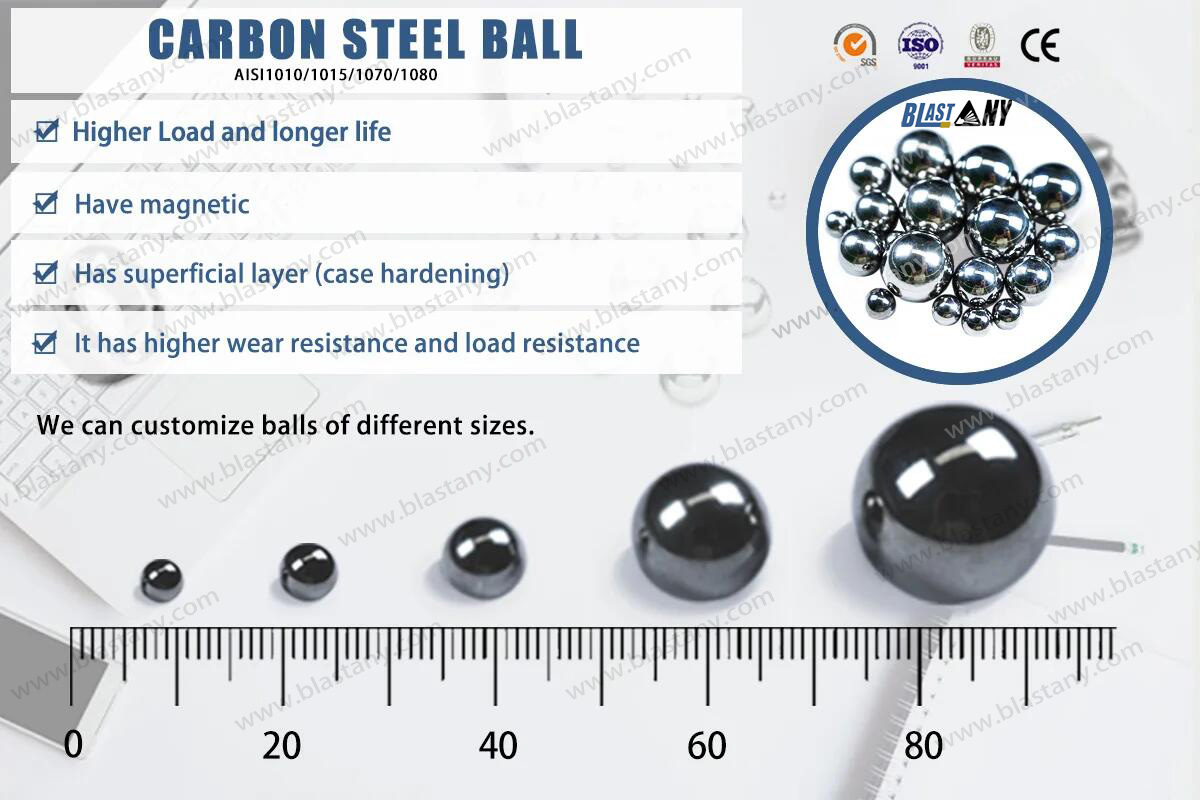

Poepoe hao hao haahaa.

Mea: AISI1010/1015

Nui Nui:0.8mm-50.8mm

Papa:G100-G1000

Paʻakiki: HRC:55-65

Nā hiʻohiʻona

loaʻa ka magnetic , Carbon Steel Balls he papa papa (case hardening), aʻo ka ʻaoʻao o loko o ka pōleʻa e mau ana ka metallographic tructure palupalu ferrite, pūʻolo pinepine me ka aila.ʻO ka electroplating maʻamau i waho o ka ʻili, hiki ke uhi ʻia me ka zinc, gula, nickel, chrome a pēlā aku.Loaʻa i ka hana anti-wear ikaika . Hoʻohālikelike: ʻaʻole maikaʻi ka ʻaʻahu a me ka paʻakikī ma mua o ka lawe ʻana i ke kinipōpō kila (ʻO ka HRC o GCr15 ka pōleʻa kila he 60-66): no laila, ʻoi aku ka pōkole o ke ola.

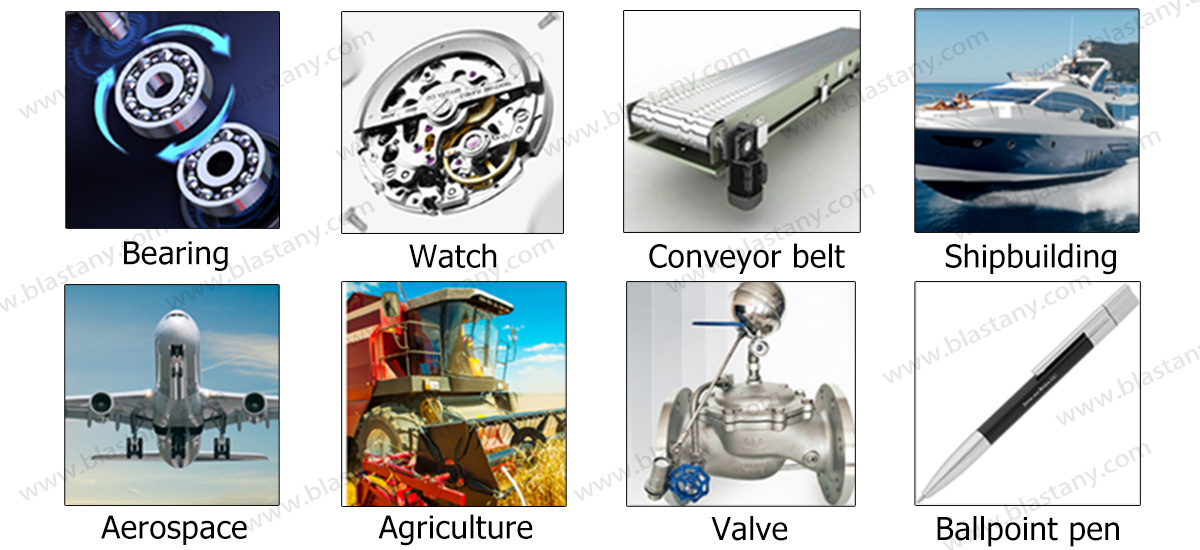

Noi: 1010/1015 ka poepoe kalapona he pōpō kila maʻamau, he haʻahaʻa ke kumu kūʻai, kiʻekiʻe ka pololei a me ka hoʻohana ākea.Hoʻohana ʻia ia i loko o ke kaʻa kaʻa, nā bearings, ka huila kaulahao, ka hana hana, ka papa, nā kinipōpō versatile, nā ʻeke, nā lako liʻiliʻi, hiki ke hoʻohana ʻia no ka hamo ʻana i nā mea ʻē aʻe. A me ka puka aniani, na mea paani, ke kaei a me na mea hoolele, ka hoopau ana.

| KE ANO O KA MEA | C | Si | Mn | P (MAX.) | S (MAX.) |

| AISI 1010 (C10) | 0.08-0.13 | 0.10-0.35 | 0.30-0.60 | 0.04 | 0.05 |

| AISI 1015 (C15) | 0.12-0.18 | 0.10-0.35 | 0.30-0.60 | 0.04 | 0.05 |

Poepoe kila kiʻekiʻe

| Material: | AISI1085 |

| Nui: | 2mm-25.4mm |

| Papa: | G100-G1000 |

| Paʻakiki: | HRC 50-60 |

Nā hiʻohiʻona

AISI1070/1080 Carbon Steel Balls, & High carbon steel balls he mea maikaʻi loa ma ke ʻano o ka helu paʻakikī holoʻokoʻa, ʻo ia hoʻi ma kahi o 60/62 HRC a hāʻawi i ka ʻaʻahu kiʻekiʻe aʻe a me ke kūpaʻa haʻahaʻa i hoʻohālikelike ʻia me nā pōpō kila paʻakikī haʻahaʻa.

(1) Paʻa paʻakikī

(2) Ke kū'ē haʻahaʻa i ka hoʻouka kaua

(3) Loaʻa kiʻekiʻe a ʻoi aku ka lōʻihi o ke ola ma mua o ka pōpō kila kalapona haʻahaʻa

Noi: ʻO nā lako kaʻa kaʻa kaʻa, nā ʻeke kinipōpō lako, nā alakaʻi sliding, nā kāʻei conveyor, nā huila haʻahaʻa kaumaha, nā ʻāpana kākoʻo pōpō.ʻO nā bearings haʻahaʻa haʻahaʻa, nā paikikala a me nā ʻāpana kaʻa, agitators, skates, polishing and milling machines, Low precision bearings.

| KE ANO O KA MEA | C | Si | Mn | P (MAX.) | S (MAX.) |

| AISI 1070 (C70) | 0.65-0.70 | 0.10-0.30 | 0.60-0.90 | 0.04 | 0.05 |

| AISI 1085 (C85) | 0.80-0.94 | 0.10-0.30 | 0.70-1.00 | 0.04 | 0.05 |

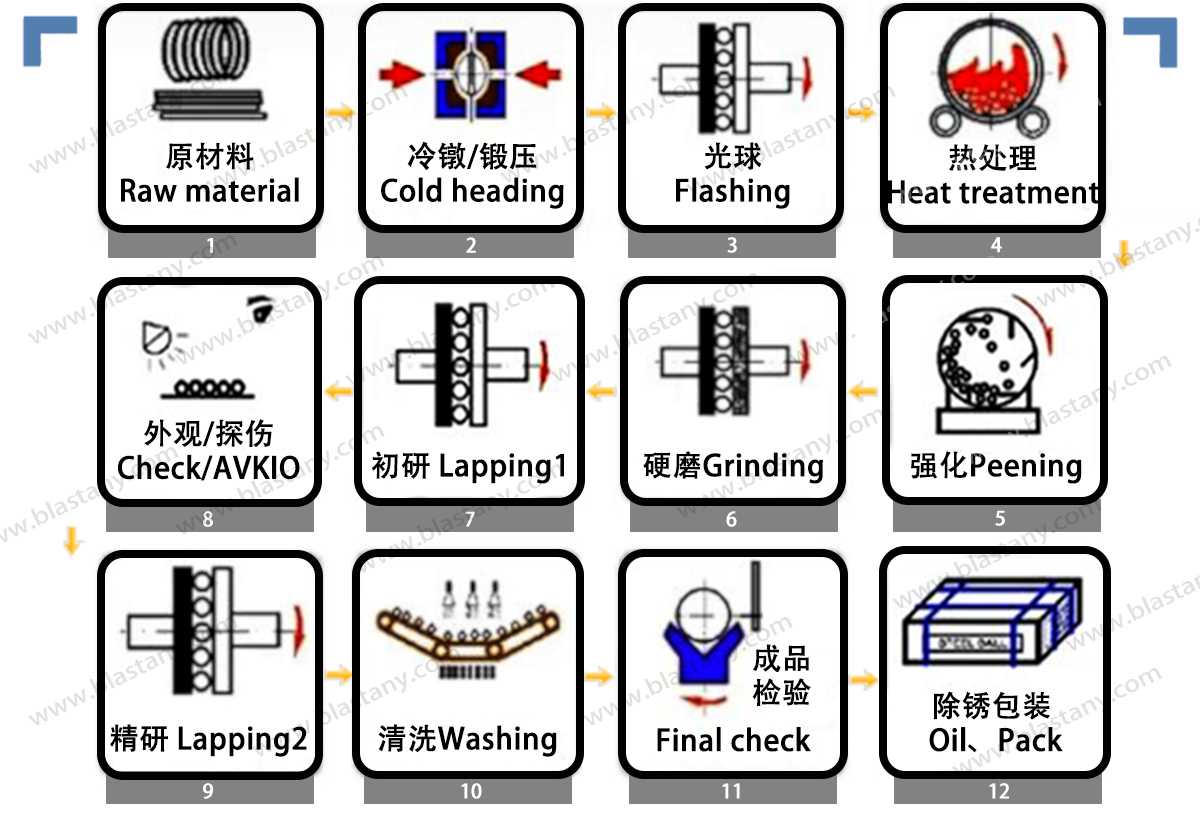

Kaʻina hana hana

ʻO ke kaʻina hana o nā huahana kinipōpō pololei

1.Law Material

I kona hoʻomaka ʻana, hoʻomaka ka pōpō ma ke ʻano uea a i ʻole ke ʻano lāʻau.E hele ana ka mana o ka maikaʻi ma ka hoʻāʻo metallurgic e hōʻoia i ka hoʻokumu ʻana o nā mea i loko o nā pae ʻae ʻia.

2. Poʻomanaʻo

Ma hope o ka hala ʻana o ka nānā ʻana o ka mea maka, a laila hānai ʻia ma o ke poʻo kiʻekiʻe.Hoʻokumu kēia i nā pōpō ʻalaʻala loa.

3. Ka uila

Hoʻomaʻemaʻe ke kaʻina hana uila i nā pōpō poʻo i ʻano maʻalahi ke ʻano.

4.Heat lapaʻau

He kaʻina hana wela kiʻekiʻe loa kahi e hoʻokomo ʻia ai nā pōpō uila i loko o ka umu ʻoihana.Hoʻopaʻakikī kēia i ke kinipōpō.

5. Ka wili ʻana

Hoʻopili ʻia ka pōpō i ke anawaena o ka nui o ka pōleʻa hope.

6. Lapili

ʻO ka paʻi ʻana o ka pōleʻa e lawe i ka nui hope i makemake ʻia.ʻO kēia ke kaʻina hana hope loa a loaʻa ka pōleʻa i loko o nā ʻae ʻana o ka papa.

7. Nānā hope loa

A laila e ana pono ʻia ka pōleʻa a nānā ʻia e ka Mana Mana e hōʻoia i ka maikaʻi loa.

Māhele huahana